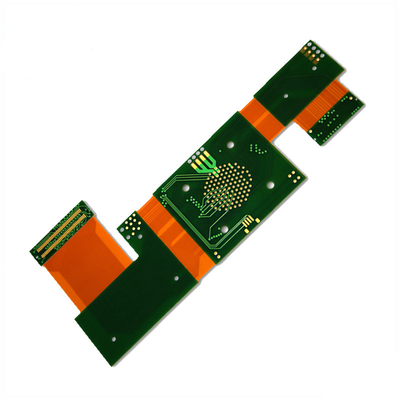

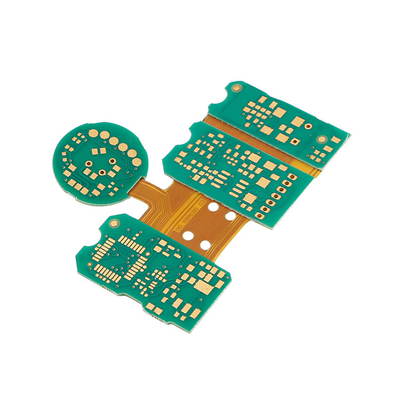

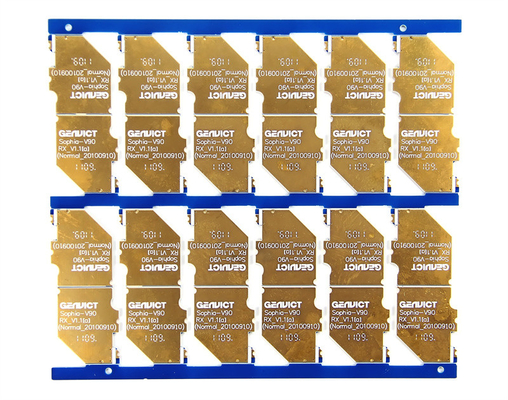

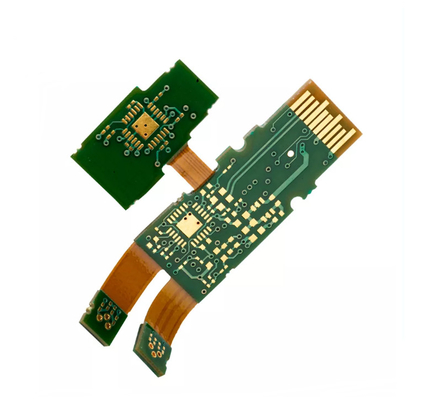

EMS FPC 2 Layer Flex Rig PCB Prototype Printed Circuit Board

| Min. Line Width | 0.075mm/0.075mm(3mil/3mil) | Surface Finishing | ENIG |

|---|---|---|---|

| Copper Thickness | 1oz | Base Material | FR4 |

| Min. Line Spacing | 0.075mm | Board Thickness | 1.6mm |

| Min. Hole Size | 0.25mm | Soldermask Color | Green |

| Silkscreen Color | White | Layer | 1-32L |

| High Light | EMS FPC 2 layer flex pcb,EMS Prototype Printed Circuit Board,FPC Prototype Printed Circuit Board |

||

China EMS factory price FPC 2-Layer Flex Rig PCB High Quality Printed Circuit Board

IBE is a full-service EMS (Electronic Manufacturing Service) contract manufacturer based in China that provides small to medium volume PCB fabrication and EMS.

Established in 2005, IBE have three manufacturing locations in China,US,Vietnam . In our PCB facility, we produce simple to complex products from 1 to 40 layers. In our EMS facility, we can do conventional thru-hole assembly, SMT assembly including BGA assembly, turnkey box build, supply chain management, project management, new product introduction, testing and product development.

![]()

![]()

![]()

![]()

![]()

PCBA Capability

The main SMT production line consists of automated high-precision state-of-the-art equipments from PanasonIC,Sumsung, Japan total 6 lines (Smallest SMT components size can reach to 0201,capable of 0.6mm*0.3mm ~ 50mm*50mmQFP, 0.15mm gap, ±0.05 accuracy ),

EMS capacity can reach 150,000,000 components per month.

Our engineering team has extensive experience in DFM/DFA/DFT technologies.

SMT, BGA Rework, Re-balling, X-Ray are all readily achieveable. Stencils can

be cut and delivered inside of 4 hours.

| PCB Assembly Capability | |

| Stencil size range: | 1560*450mm |

| Min SMT package: | 0402/1005(1.0x0.5mm) |

| Min IC pitch: | 0.3mm |

| Max PCB Size: | 1200*400mm |

| Min PCB thickness: | 0.35mm |

| Min Chip Size: | 01005 |

| Max BGA Size: | 74*74mm |

| BGA Ball Pitch: | 1.00~3.00mm |

| BGA Ball Diameter: | 0.4~1.0mm |

| QFP Lead Pitch: | 0.38~2.54mm |

| Testing : | ICT,AOI,X-RAY,Funtional test etc. |

|

Order Conditions

|

Standard Delivery Date

|

The fastest Delivery Date

|

|

Prototype ( <20pcs)

|

2days

|

8hours

|

|

Small Volume (20-100pcs)

|

6days

|

12hours

|

|

Medium Volume (100-1000)

|

3days

|

24hours

|

|

Mass Production (>1000)

|

Depends on BOM

|

Depends on BOM

|

FAQ:

1.How does a printed circuit board assembly (PCB assembly) work?

![]()

The primary function of a PCB assembly is to integrate the electronic components of a device into a compact or defined space. Acting as the central hub of the electronic circuit of a device, the PCB provides insulation for all other electrical components, allowing them to be safely connected to a power source.

2. What information is required for a turnkey PCB assembly order?

For turnkey projects, we’ll need the following:

Gerber file

Bill of materials (BOM)

Component placement list (CPL)

All relevant CAD and .stp file

3. Are you UL / Underwriters Laboratory approved?

IBE pursues all applicable UL certifications for our products, and we offer several products certified with UL and CSA based on customer’s demand

Underwriters Laboratories (UL) grants multiple certifications, including:

IBE is certified for PCB by UL file E326838

4. Do you offer RoHS&REACH-compliant assemblies?

Yes, IBE does offer assemblies that comply with the European Union’s Restriction of Hazardous Substances (RoHS) Directive and REACH.

5. Do you offer testing and inspection services?

Yes, IBE offers a comprehensive list of testing and inspection services for both SMT and through-hole assemblies.

Visual inspection/scanning microscopes

AOI inspection

In-circuit test

Functional testing include automated test equipment and system

Burn-in tests

Low/High Temp Chamber Testing

X-ray inspection and repair

Salt fog tester

Drop Test

packing vibration

Conformal coating and potting

6. What are your PCB assembly standards?

IBE has obtained the following IPC electronics industry standards for PCB assembly

IPC-A-600G for PCB production

IPC-620 for practices and requirements for cables, wire, and harness assembly manufacturing

IPC-A-610E PCBA Acceptability of Electronic Assemblies

7.Can you ship to my contract manufacturer for the final build?

Yes, we can ship your assemblies for final production. We can also offer turnkey, box build, and labor-only services