High TG PCB Prototype Electronics Assembly HASL Lead Free

| Place of Origin | CHINA,VIETNAM,USA |

|---|---|

| Brand Name | IBE |

| Certification | IATF/TS16949,ISO13485,ISO 9001,ISO14001,UL |

| Model Number | IBE-1697432 |

| Minimum Order Quantity | no MOQ |

| Price | Negotiable |

| Packaging Details | ESD bag+card carton(custom made) |

| Delivery Time | 5-10 weeks depends on components lead time |

| Payment Terms | L/C, T/T |

| Supply Ability | 20000pcs+unit+month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

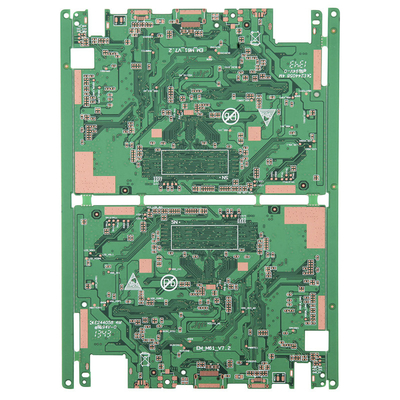

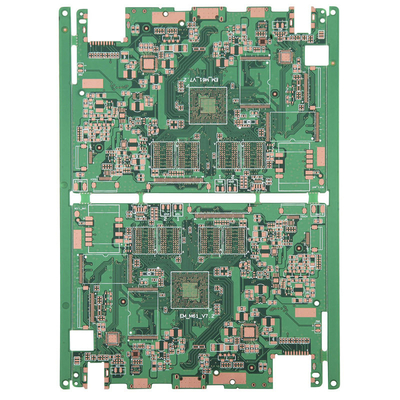

x| Material | FR4, FR4 CEM1 CEM3 Hight TG | Layers | 1-24layers, 1-28 L |

|---|---|---|---|

| Copper Thickness | 1oz, 0.25 Oz -12 Oz, 1/2OZ 1OZ 2OZ 3OZ, 1-4oz, 3oz | Surface Finishing | HASL, ENIG, OSP, Immersion Gold, HASL Lead Free |

| Solder Mask | Green, Green. Red. Blue. White. Black.Yellow, Blue, Purple, Yellow | Type | Electronic Board, PCBA Design Service |

| Highlight | High TG Prototype Electronics Assembly,HASL lead free pcb assembly,high tg pcb Prototype Electronics Assembly |

||

Prototype PCBA, Automotive PCBA, circuit pcb, PCB quick production,PCB

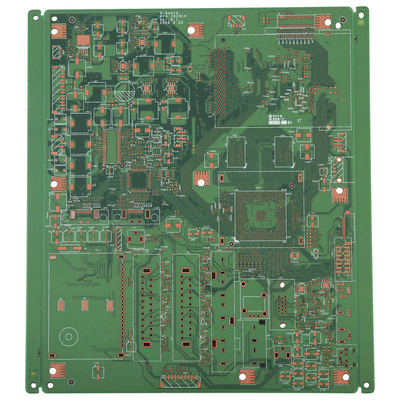

IBE Manufacturing’s facility is specifically designed to yield a J-STD-001 Class 3 board, sub-assembly and system every time. From our stencils, to selective and surface mount automation, to our automated optical inspection, to final assembly, inspection and test, we are committed to quality. We have an onsite CIT trainer to provide on-going J-STD training and continuing education to our production team. This means our team is always current with industry standards and able to build, inspect and test to Class 3 standards.

Our Advantages:

1, Factory Area:60000㎡ Shenzhen factory; two other factories in US and Vietnam.

2, PCB Making (Rigid, Flexible,Rigid-Flexible,Aluminium, High TG,Ceramic), Component Sourcing, SMT&DIP, Free Program & Test, OEM/ODM Serivce

3, Certifcation:ATF 16949,ISO 13485,ISO 14001,ISO9001,UL(E326838),Disney FAMA, CE,FCC,ROHS,

| 1 | Material | PR4,Halogen free, High TG,CEM3,PTFE,Aluminum BT,Rogers |

| 2 | Board Thickness | Mass Production:0.3-3.5mm Samples:0.21-6.0mm |

| 3 | Surface Finish | HASL,OSP,Immersion Silver/Gold/SN,Flash Gold, Gold Finger,Hard Gold Plating |

| 4 | PCB Panel Size | Max Mass Productoin: 610x460mm Sample:762x508mm |

| 5 | Layer | Mass production:2-58 Layers, Samples:1-64 Layers |

| 6 | Min. Drill Hole Size | Laser Drill 0.1mm,Machine Drill 0.2mm |

| 7 | PCBA QC | X-ray,AOI Test,Functional Test |

| 8 | Speciality | Automotive,Medical/Gaming/Smart Device,Computer,LED/Lighting,etc |

| 9 | Sanforized | Buried via, Blind via, Mixed Pressure,Embedded Resistance,Embedded Capacitance, Local Mixed Pressure, Local High Density, Back Drill, Impedance Control |

![]()

![]()

![]()

FAQ:

1.How does a printed circuit board assembly (PCB assembly) work?

![]()

The primary function of a PCB assembly is to integrate the electronic components of a device into a compact or defined space. Acting as the central hub of the electronic circuit of a device, the PCB provides insulation for all other electrical components, allowing them to be safely connected to a power source.

2. Are you UL / Underwriters Laboratory approved?

IBE pursues all applicable UL certifications for our products, and we offer several products certified with UL and CSA based on customer’s demand

Underwriters Laboratories (UL) grants multiple certifications, including:

IBE is certified for PCB by UL file E326838

3. Do you offer testing and inspection services?

Yes, IBE offers a comprehensive list of testing and inspection services for both SMT and through-hole assemblies.

Visual inspection/scanning microscopes

AOI inspection

In-circuit test

Functional testing include automated test equipment and system

Burn-in tests

Low/High Temp Chamber Testing

X-ray inspection and repair

Salt fog tester

Drop Test

packing vibration

Conformal coating and potting

4. What are your PCB assembly standards?

IBE has obtained the following IPC electronics industry standards for PCB assembly

IPC-A-600G for PCB production

IPC-620 for practices and requirements for cables, wire, and harness assembly manufacturing

IPC-A-610E PCBA Acceptability of Electronic Assemblies