IBE Surface Mount Quick Turn PCB Assembly AOI FCT Test Full Turnkey

| Place of Origin | CHINA,VIETNAM,USA |

|---|---|

| Brand Name | IBE |

| Certification | IATF16949,ISO13485,ISO 9001,ISO14001,ISO45001,UL,FDA |

| Model Number | IBE-9262 |

| Minimum Order Quantity | 1pc |

| Price | $USD12-18 unit |

| Packaging Details | ESD bag+card carton(custom made) |

| Delivery Time | 4-20 weeks depends on components lead time |

| Payment Terms | L/C, T/T |

| Supply Ability | 100000pcs |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

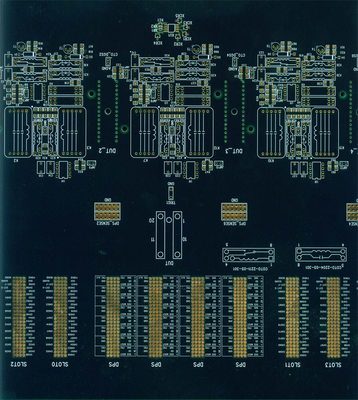

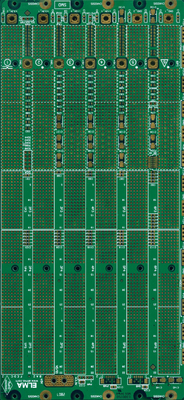

x| Colour | Green | Name | PCBA |

|---|---|---|---|

| Surface Technical | ENIG | Layer Count | 10 |

| Material | FR4 | Max Panel Size | 750mm*708mm |

| Acceptable Standard | IPC-A-600G Class II Or III | Service | One-stop Quick Turnkey Service |

| Test | AOI,FCT,ICT | Type | OEM |

| Highlight | Full Turnkey surface mount pcb assembly,IBE full turnkey pcb assembly,AOI FCT full turnkey pcb assembly |

||

Quick Turn PCB Electronic Assembly manufacturer globally plants

At the component assembling stage, manufacturers can use the following technologies:

Surface-Mount Assembly (SMT) - With this technique, electrical components are mounted directly on the board stackup and fastened using soldering materials.

Through-Hole Assembly (THA) - Here, the technicians and engineers mount and solder through-hole components on the empty boards.

Mixed Assembly - The quick turn PCB producer combines the SMT and THA techniques.

After assembling and testing the PCB, the product is packaged and delivered to the client.

![]()

About IBE Corporation

Certification:

Certified by ISO 9001 and 14001,IBE is a well-equipped and strictly managed manufacturer.We integrate our resources and manage production through MES system which can well optimize process and guarantee quality.Besides,IBE Group adheres strictly to the production and manufacturing standards of IATF16949,automobile industry and ISO 13485,medical industry.

![]()

Production capability:

| SMT and Through-Hole Assembly | Fine Pitch Component Insertion |

| Lead free Assembly | BGA and QFN Assembly |

| One-stop PCB Assembly | BGA X-Ray Inspection |

| Prototype PCB Assembly | Automated Optical Inspection |

| PCB Assembly in low volumes | PCB testing for functionality |

| AOI Testing Checks for solder paste Checks for components down to 0201" Checks for missing components, offset, incorrect parts, polarity X-Ray Inspection X-Ray provides high-resolution inspection |

In-Circuit Testing In-Circuit Testing is commonly used in conjunction with AOI minimizing functional defects caused by component problems. Power-up Test Advanced Function Test Flash Device Programming Functional testing |

| Selective Wave Soldering | Conformal Coating |

| Complete box build | Kitting and 3D printing |

FAQ:

Q: What service do you have?

A: We provide PCB,components sourcing,PCB assembly,box build,R &D services.

Q: What is your minimum order quantity (MOQ)?

A:As for MOQ, we have no request about it. Even 1 pcs is ok for us.

Q: What is needed for PCB & PCBA quotation?

A: Gerber fie,Bom list and production technical requirements.

Q: How to keep our product information and design file secret ?

A: We are willing to sign a NDA effect by customers side local law and promising tokeep customers data in high confidential level.