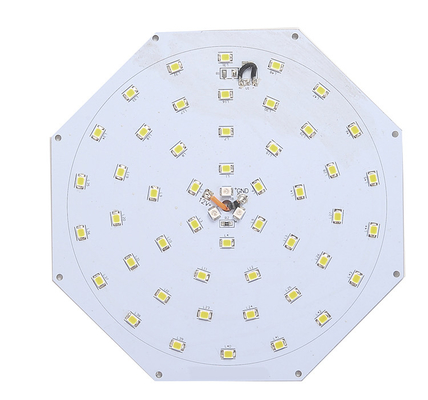

2 Layer LED Light Bulb Circuit Board HASL Round Aluminium AC PCB Board

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Min. Line Width | 0.075mm/0.075mm(3mil/3mil) | Surface Finishing | ENIG |

|---|---|---|---|

| Copper Thickness | 1oz | Base Material | FR4 |

| Min. Line Spacing | 0.075mm | Board Thickness | 1.6mm |

| Min. Hole Size | 0.25mm | Soldermask Color | Green |

| Silkscreen Color | White | Layer | 1-32L |

| Highlight | 2 Layer LED Light Bulb Circuit Board,LED Light Bulb Circuit Board HASL,HASL Round Aluminium AC PCB Board |

||

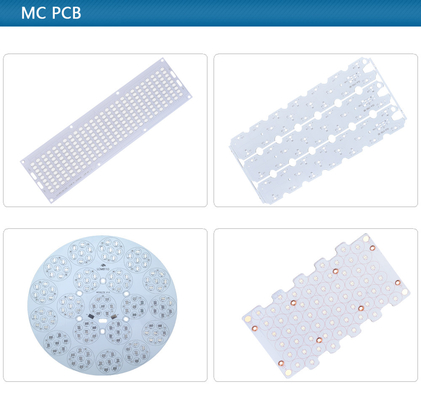

Aluminium Round LED Bulb Light AC PCB Board/Metal Circuit PCB 2L Alu PCB

IBE Electronics Limited was established in 2005, provide one-stop services for PCB manufacturing , component sourcing, PCB assembly and testing .We have own pcb factories and SMT production lines, and a variety of professional testing equipments, company owned experienced professional and technical R & D technology team, young and professional sales and customer service teams, experienced and professional procurement team and assembly testing team, which make sure the products quality of the pass rate, on-time delivery rate of customer orders.

| PCB Manufacturing Capability | |

| PCB Layers: | 1Layers to 18 layer (Max) |

| Board thickness: | 0.13~6.0mm |

| Min line width/space: | 3mil |

| Min mechanical hole size: | 4mil |

| Copper thickness: | 9um~210um(0.25oz~6oz) |

| Max aspect ratio: | 1:10 |

| Max board size: | 400*700mm |

| Surface Finish: | HASL, immersion gold, immersion silver,immersion tin, flash gold, gold finger,peelable mask |

| Material: | FR4,High Tg, Rogers, CEM-1, CEM-3, Aluminum BT, PTFE. |

| PCB Assembly Capability | |

| Stencil size range: | 1560*450mm |

| Min SMT package: | 0402/1005(1.0x0.5mm) |

| Min IC pitch: | 0.3mm |

| Max PCB Size: | 1200*400mm |

| Min PCB thickness: | 0.35mm |

| Min Chip Size: | 01005 |

| Max BGA Size: | 74*74mm |

| BGA Ball Pitch: | 1.00~3.00mm |

| BGA Ball Diameter: | 0.4~1.0mm |

| QFP Lead Pitch: | 0.38~2.54mm |

| Testing : | ICT,AOI,X-RAY,Funtional test etc. |

FAQ:

1.How does a printed circuit board assembly (PCB assembly) work?

![]()

The primary function of a PCB assembly is to integrate the electronic components of a device into a compact or defined space. Acting as the central hub of the electronic circuit of a device, the PCB provides insulation for all other electrical components, allowing them to be safely connected to a power source.

2. What information is required for a turnkey PCB assembly order?

For turnkey projects, we’ll need the following:

Gerber file

Bill of materials (BOM)

Component placement list (CPL)

All relevant CAD and .stp file

3. Are you UL / Underwriters Laboratory approved?

IBE pursues all applicable UL certifications for our products, and we offer several products certified with UL and CSA based on customer’s demand

Underwriters Laboratories (UL) grants multiple certifications, including:

IBE is certified for PCB by UL file E326838

4. Do you offer RoHS&REACH-compliant assemblies?

Yes, IBE does offer assemblies that comply with the European Union’s Restriction of Hazardous Substances (RoHS) Directive and REACH.

5. Do you offer testing and inspection services?

Yes, IBE offers a comprehensive list of testing and inspection services for both SMT and through-hole assemblies.

Visual inspection/scanning microscopes

AOI inspection

In-circuit test

Functional testing include automated test equipment and system

Burn-in tests

Low/High Temp Chamber Testing

X-ray inspection and repair

Salt fog tester

Drop Test

packing vibration

Conformal coating and potting