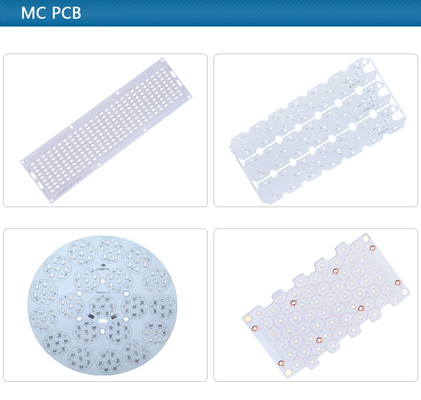

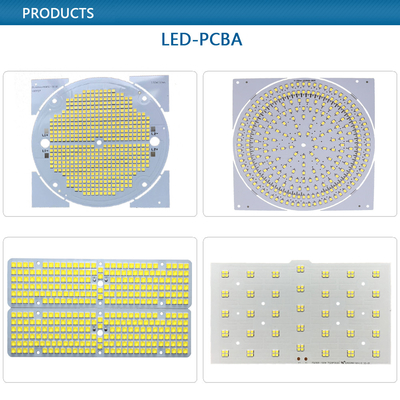

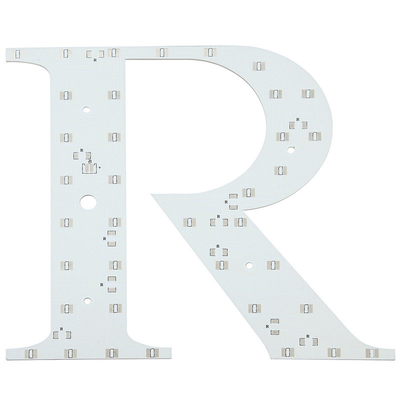

Immersion Gold 2L Alu PCB OSP Led Light Bulb Circuit Board

| Place of Origin | China |

|---|---|

| Brand Name | IBE |

| Certification | ISO/TS16949 ISO13485 |

| Model Number | Electricity Meter PCBA |

| Minimum Order Quantity | 10 |

| Price | $0.1-$0.5 |

| Packaging Details | ESD bag/vacuum packaging |

| Delivery Time | 5-7 working days |

| Payment Terms | D/A, L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 50000pcs/week |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Min. Line Width | 0.075mm/0.075mm(3mil/3mil) | Surface Finishing | HASL,Immersion Gold,Flash Gold, Plated Silver, OSP, HASL |

|---|---|---|---|

| Copper Thickness | 1oz | Base Material | FR4 |

| Min. Line Spacing | 0.075mm | Board Thickness | 1.6mm |

| Min. Hole Size | 0.25mm | Layer | 1-32L |

| Material | Aluminium, Copper, CEM-1, CEM-3 And FR4 Material | ||

| Highlight | Immersion Gold 2L Alu PCB OSP,OSP Led Light Bulb Circuit Board,2L Alu Led Light Bulb Circuit Board |

||

2L Alu OSP PCB High Tg Fr-4 Eing with Stable Good Quality for led bulb

Company Capability

| PCB Manufacturing Capability | |

| PCB Layers: | 1Layers to 18 layer (Max) |

| Board thickness: | 0.13~6.0mm |

| Min line width/space: | 3mil |

| Min mechanical hole size: | 4mil |

| Copper thickness: | 9um~210um(0.25oz~6oz) |

| Max aspect ratio: | 1:10 |

| Max board size: | 400*700mm |

| Surface Finish: | HASL, immersion gold, immersion silver,immersion tin, flash gold, gold finger,peelable mask |

| Material: | FR4,High Tg, Rogers, CEM-1, CEM-3, Aluminum BT, PTFE. |

| PCB Assembly Capability | |

| Stencil size range: | 1560*450mm |

| Min SMT package: | 0402/1005(1.0x0.5mm) |

| Min IC pitch: | 0.3mm |

| Max PCB Size: | 1200*400mm |

| Min PCB thickness: | 0.35mm |

| Min Chip Size: | 01005 |

| Max BGA Size: | 74*74mm |

| BGA Ball Pitch: | 1.00~3.00mm |

| BGA Ball Diameter: | 0.4~1.0mm |

| QFP Lead Pitch: | 0.38~2.54mm |

| Testing : | ICT,AOI,X-RAY,Funtional test etc. |

|

Order Conditions

|

Standard Delivery Date

|

The fastest Delivery Date

|

|

Prototype ( <20pcs)

|

2days

|

8hours

|

|

Small Volume (20-100pcs)

|

6days

|

12hours

|

|

Medium Volume (100-1000)

|

3days

|

24hours

|

|

Mass Production (>1000)

|

Depends on BOM

|

Depends on BOM

|

FAQ:

1.How does a printed circuit board assembly (PCB assembly) work?

![]()

The primary function of a PCB assembly is to integrate the electronic components of a device into a compact or defined space. Acting as the central hub of the electronic circuit of a device, the PCB provides insulation for all other electrical components, allowing them to be safely connected to a power source.

2. What information is required for a turnkey PCB assembly order?

For turnkey projects, we’ll need the following:

Gerber file

Bill of materials (BOM)

Component placement list (CPL)

All relevant CAD and .stp file

3. What are your PCB assembly standards?

IBE has obtained the following IPC electronics industry standards for PCB assembly

IPC-A-600G for PCB production

IPC-620 for practices and requirements for cables, wire, and harness assembly manufacturing

IPC-A-610E PCBA Acceptability of Electronic Assemblies

4.Can you ship to my contract manufacturer for the final build?

Yes, we can ship your assemblies for final production. We can also offer turnkey, box build, and labor-only services

5.Where do you manufacture your products?

We have production plant based in shenzhen,China; Fremont,US,Bac Ninh,Vietn