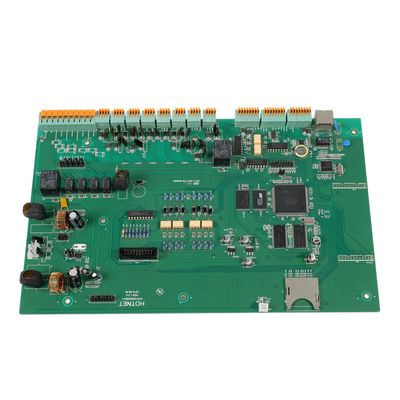

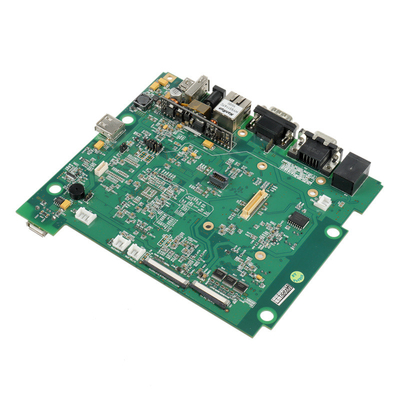

High Frequency Industrial PCB Assembly Design 0.13-6.0mm Thickness

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Rogers | Colour | Black |

|---|---|---|---|

| Size | 230mm*70mm | Surface | ENIG |

| Layer | 10 | Name | Industrial Automation PCB Assembly |

| Highlight | Industrial PCB Assembly 6.0mm Thickness,high frequency pcb design 6.0mm Thickness,High Frequency Industrial PCB Assembly |

||

![]()

![]()

![]()

![]()

PCBA Capability

| PCB Manufacturing Capability | |

| PCB Layers: | 1Layers to 18 layer (Max) |

| Board thickness: | 0.13~6.0mm |

| Min line width/space: | 3mil |

| Min mechanical hole size: | 4mil |

| Copper thickness: | 9um~210um(0.25oz~6oz) |

| Max aspect ratio: | 1:10 |

| Max board size: | 400*700mm |

| Surface Finish: | HASL, immersion gold, immersion silver,immersion tin, flash gold, gold finger,peelable mask |

| Material: | FR4,High Tg, Rogers, CEM-1, CEM-3, Aluminum BT, PTFE. |

| PCB Assembly Capability | |

| Stencil size range: | 1560*450mm |

| Min SMT package: | 0402/1005(1.0x0.5mm) |

| Min IC pitch: | 0.3mm |

| Max PCB Size: | 1200*400mm |

| Min PCB thickness: | 0.35mm |

| Min Chip Size: | 01005 |

| Max BGA Size: | 74*74mm |

| BGA Ball Pitch: | 1.00~3.00mm |

| BGA Ball Diameter: | 0.4~1.0mm |

| QFP Lead Pitch: | 0.38~2.54mm |

| Testing : | ICT,AOI,X-RAY,Funtional test etc. |

| Material Type | Item | Min | Max |

| PCB | Dimension (length,width,height.mm) | 30*40*0.38 | 700*400*4.2 |

| Weight | 1.8KG | ||

| Special dimension | 1400*400*4.2 | ||

| Material | FR-4,CEM-1,CEM-3,Aluminium-based board,FPC | ||

| Surface finish | HASL,OSP,Immersion gold,Flash Gold Finger | ||

| Components | Chip&IC | 0201(0.5*0.25) | 55mm |

| BGA Pitch | 0.2mm | ||

| QFP Pitch | 0.3mm | ||

Industries IBE serves for:

Industry control

Automotive Electronics

Medical Care

Consumer Electronics

Telecom and Security

Metering and Instrument

Energy

LED lighting and display

What Services IBE provides:

IBE PCBA capabilities include:

Fast prototyping

High mix, low/medium volume build

Surface mounting technology (SMT MinChip:0201) and Ball Grid Array (BGA: 1.0 to 3.0 mm pitch)

Through-hole assembly

Special processes (such as conformal coating and potting)

ROHS capability

IPC-A-610E and IPC/EIA-STD workmanship operation

UL Certificated: E326838

Test solutions include:

Automatic optical inspection(AOI)

In-circuit test (ICT)

Reliability test

X-Ray Test

Analogue and digital function test

Firmware programming

Quality Assurance:

ISO9001 and ISO14001 management systems

Lean production system

ERP and PTS system support for management

IBE believe that only by always delivering the products that meet or exceed your quality requirements, could we earn your continuous trust as your reliable EMS partner.

In order to assure the quality in every level of assembly, we employ a strict quality management system to control the whole production process.

Our Quality processes include:

1. IQC: Incoming Quality Control (Incoming Materials Inspection)

2. First Article Inspection for every process

3. IPQC: In Process Quality Control

4. QC: 100% Test & Inspection

5. QA: Quality Assurance based on QC inspection again

6. Workmanship: IPC-A-610, ESD

7. Quality Management based on CQC, ISO9001:2008, ISO 14001:2004

Supply Chain:

We have a professional procurement team with rich experience in sourcing molding, stamping, forming, and injection. And we employ a comprehensive supply chain evaluation system for our suppliers.

In order to choose the best options for our customers' needs on overall competitiveness, IBE would benchmark all our suppliers, based on their quality and environment management systems, flexibility, services, capacity, sustainability, and total cost of ownership.

Both our procurement and engineer team work with all our customers at the initial quote stage to devise the most suitable and competitive sourcing strategy for our customers, based on their product requirements and under their confirmation. In this way, we could indentify and catch every cost reduction opportunities for the customers and reach the lowest total cost of the project.