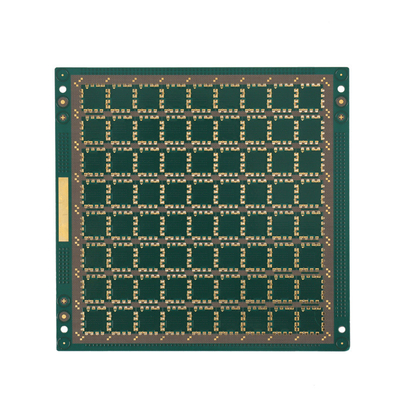

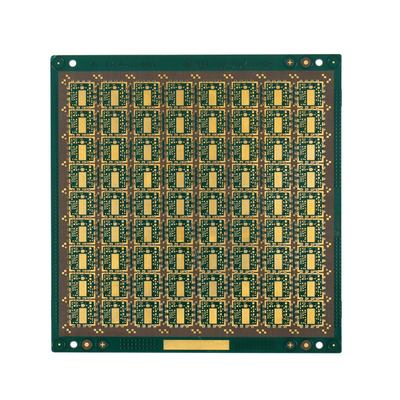

1oz Copper Thickness 2 Layers PCB Circuit Board FR4 Tg140 Halogen Free

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | FR4 Tg140 Shengyi | Colour | Green,yellow,blue |

|---|---|---|---|

| Copper Thickness | 1oz | Acceptable Standard | IPC-A-610F Class II Or III |

| Surface Finish | ENIG | Type | Custom Made |

| Product Name | Printed Circuit Board | Application | Communication Phone |

| Pcb Test | Electrical Test | Min.hole Size | 0.15mm |

| Silkscreen Color | White,yellow | Layers | 2 |

| Size | 21*20mm | Special | No X-out |

| Highlight | 1oz Copper Thickness 2 Layers PCB,Halogen free 2 layer circuit board,FR4 Tg140 2 Layers PCB |

||

2-layers PCB circuit board with ENIG for smart wearable products without x-out

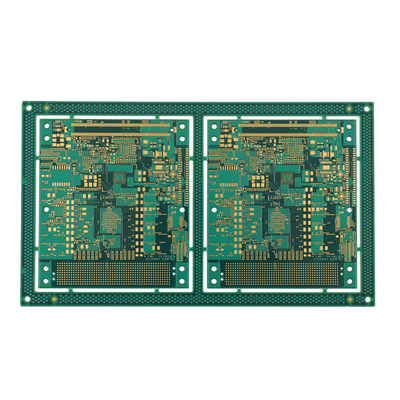

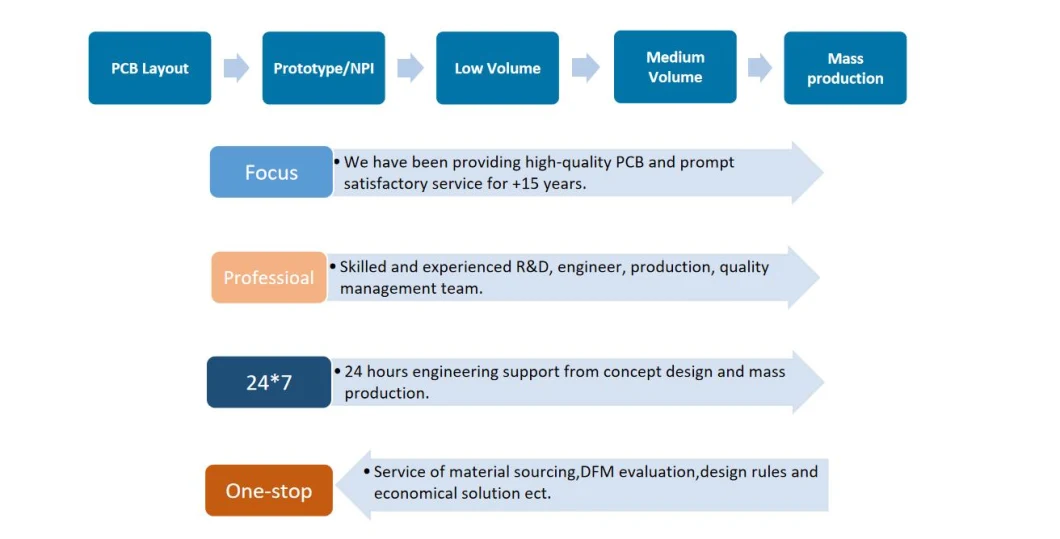

IBE provide High quality and super service to provide quick turn and mass production on rigid PCB:

| Technical Capability of rigid PCB | ||||||||||||

| Item | Mass production | Small batch production | ||||||||||

| Number of Layers | UP TO 18L | UP TO 36L | ||||||||||

| Laminate | FR-4,Halogen free, High TG,Cem-3,Al/copper based,high frequency | |||||||||||

| Maximum board size | 610*460mm | 1200*600mm | ||||||||||

| Board thickness | 0.3-3.5mm | 0.2-6.0mm | ||||||||||

| Minimum line width/space | 3/3 mil | 3/3 mil | ||||||||||

| Minimum line/space tolerance | +/-20% | +/-10% | ||||||||||

| Max.Outer layer copper thickness | 140um | 210um | ||||||||||

| Max.Inner layer copper thickness | 105um | 175um | ||||||||||

| Min. finished hole size(Mechanical) | 0.2mm | 0.15mm | ||||||||||

| Min. finished hole size (laser hole) | 0.075mm | 0.075mm | ||||||||||

| Aspect ratio | 10:1 | 12:1 | ||||||||||

| Solder Mask Color | Green, Blue, Black,White,Yellow,Red | |||||||||||

| Impedance control Tolerance | <=+/-10% | |||||||||||

| Surface treatment | Flash Gold | 0.025-0.075um | 0.025-0.5um | |||||||||

| Immersion Gold | 0.025-0.1um | 0.1-0.2um | ||||||||||

| Sn/Pb Hasl | 1-40um | |||||||||||

| Leadfree Hasl | 1-70um | |||||||||||

| Immersion Silver | 0.08-0.3um | |||||||||||

| OSP(Entek) | 0.2-0.4um | |||||||||||

| Gold Finger(Hard Gold Plating ) | 10u''-50u'' | |||||||||||

| Other surface treatment also available such as Nickel palladium | ||||||||||||

IBE Focus on one stop solution

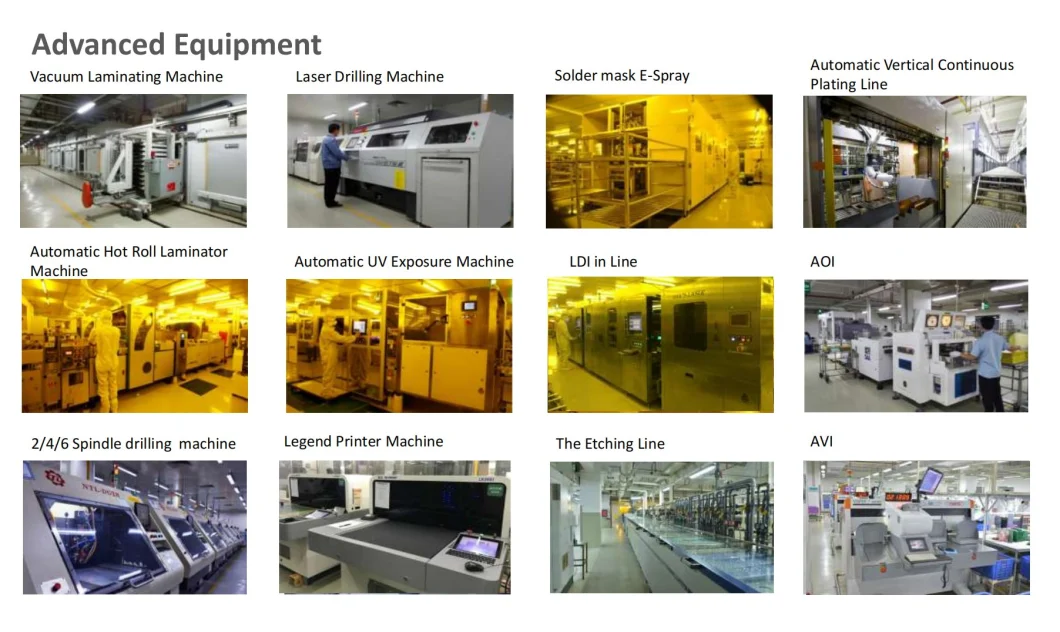

Advanced Equipment

FAQ:

1. What information is required for a turnkey PCB assembly order?

For turnkey projects, we’ll need the following:

Gerber file

Bill of materials (BOM)

Component placement list (CPL)

All relevant CAD and .stp file

2. Are you UL / Underwriters Laboratory approved?

IBE pursues all applicable UL certifications for our products, and we offer several products certified with UL and CSA based on customer’s demand

Underwriters Laboratories (UL) grants multiple certifications, including:

IBE is certified for PCB by UL file E326838

3. Do you offer RoHS&REACH-compliant assemblies?

Yes, IBE does offer assemblies that comply with the European Union’s Restriction of Hazardous Substances (RoHS) Directive and REACH.