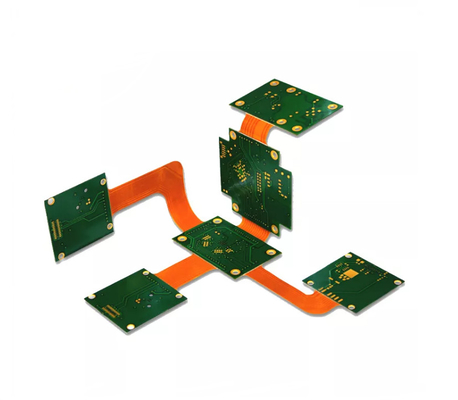

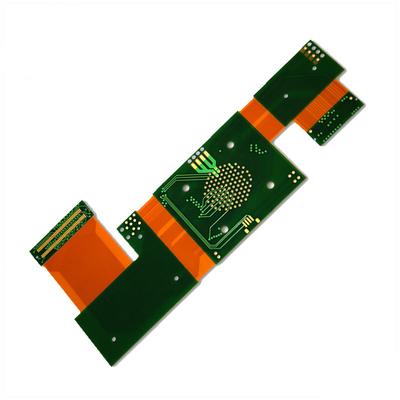

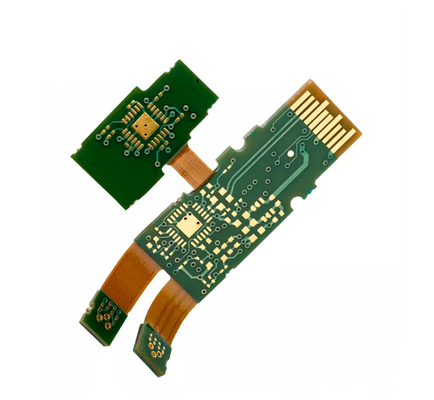

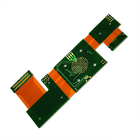

Immersion Silver Flex Rigid PCB Halogen Free 0.3-3.5mm Thickness

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Colour | Yellow | Size | 110mm*90mm |

|---|---|---|---|

| Name | PCB | Material | FR4 |

| Surface | Immersion Gold | Layer | 1-16 |

| Highlight | Immersion Silver Flex Rigid PCB,PCB Halogen Free 3.5mm Thickness,3.5mm Thickness Flex Rigid PCB |

||

Immersion Silver Flex Rigid PCB

About IBE Corporation

Founded in 2005, IBE Corporation is a mid-size provider of end-to-end electronics manufacturing services (EMS) including PCBA production, systems integration and comprehensive testing services, enclosure fabrication, as well as product design, sustaining engineering and supply chain management services. IBE facilities span a broad footprint in the China,United States and Vietnam. IBE services extend over the entire electronic product life cycle from the development and introduction of new products through to the growth, maturity and end-of-life phases.

![]()

![]()

![]()

![]()

Production capability:

| 1 | Material | PR4,Halogen free, High TG,CEM3,PTFE,Aluminum BT,Rogers |

| 2 | Board Thickness | Mass Production:0.3-3.5mm Samples:0.21-6.0mm |

| 3 | Surface Finish | HASL,OSP,Immersion Silver/Gold/SN,Flash Gold, Gold Finger,Hard Gold Plating |

| 4 | PCB Panel Size | Max Mass Productoin: 610x460mm Sample:762x508mm |

| 5 | Layer | Mass production:2-58 Layers, Samples:1-64 Layers |

| 6 | Min. Drill Hole Size | Laser Drill 0.1mm,Machine Drill 0.2mm |

| 7 | PCBA QC | X-ray,AOI Test,Functional Test |

| 8 | Speciality | Automotive,Medical/Gaming/Smart Device,Computer,LED/Lighting,etc |

| 9 | Sanforized | Buried via, Blind via, Mixed Pressure,Embedded Resistance,Embedded Capacitance, Local Mixed Pressure, Local High Density, Back Drill, Impedance Control |

Rigid flexible PCB provides a wide range of applications from smart devices to mobile phones and digital cameras. Rigid-flex PCB manufacturing has been increasingly used in medical devices such as pacemakers to reduce their space and weight. The use of rigid flex PCB has the same advantages and can be applied to intelligent control systems.