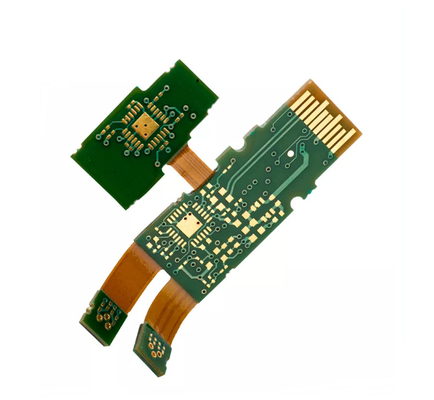

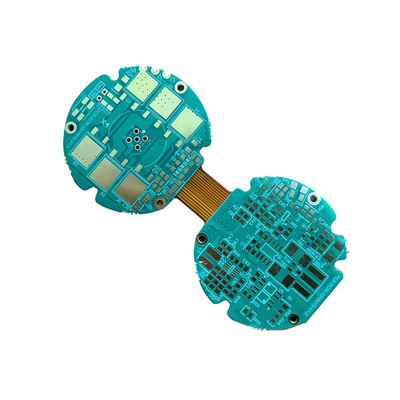

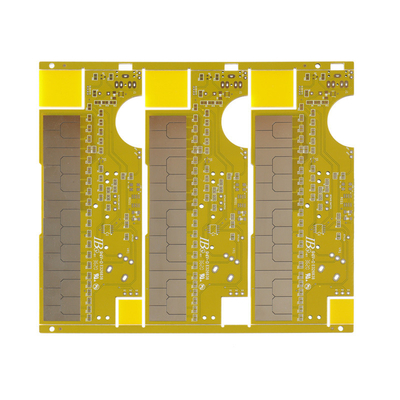

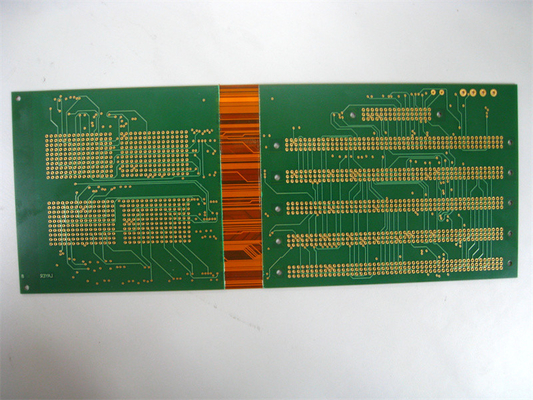

ENIG Multilayer FR4 Rigid Flex PCB For Medical Equipment

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Min. Line Width | 0.075mm/0.075mm(3mil/3mil) | Surface Finishing | ENIG |

|---|---|---|---|

| Copper Thickness | 1oz | Base Material | FR4 |

| Min. Line Spacing | 0.075mm | Board Thickness | 1.6mm |

| Min. Hole Size | 0.25mm | Soldermask Color | Green |

| Silkscreen Color | White | Layer | 1-32L |

| Highlight | ENIG Multilayer Rigid Flex PCB,Medical Equipment multilayer fr4 pcb,ENIG FR4 Rigid Flex PCB |

||

Multilayer PCB/Flexible PCB/Rigid Flex PCB /Fpcba rigid flex printed circuit board

With professional engineering and top advanced machines, our PCB production capability has been in a leading position, with smallest hole size, minimum line width/space, we can produced those difficult PCBs which other factory can not finished,our PCBs quality win higly recognition and we have develops lots of customers all over the world and win high reputation from all customers for both quality and price, our products widely used in Medical equipment, consumer electroncis, telcom, industry control and car electronics.

| PCB Assembly Capability | |

| Stencil size range: | 1560*450mm |

| Min SMT package: | 0402/1005(1.0x0.5mm) |

| Min IC pitch: | 0.3mm |

| Max PCB Size: | 1200*400mm |

| Min PCB thickness: | 0.35mm |

| Min Chip Size: | 01005 |

| Max BGA Size: | 74*74mm |

| BGA Ball Pitch: | 1.00~3.00mm |

| BGA Ball Diameter: | 0.4~1.0mm |

| QFP Lead Pitch: | 0.38~2.54mm |

| Testing : | ICT,AOI,X-RAY,Funtional test etc. |

|

Order Conditions

|

Standard Delivery Date

|

The fastest Delivery Date

|

|

Prototype ( <20pcs)

|

2days

|

8hours

|

|

Small Volume (20-100pcs)

|

6days

|

12hours

|

|

Medium Volume (100-1000)

|

3days

|

24hours

|

|

Mass Production (>1000)

|

Depends on BOM

|

Depends on BOM

|

FAQ:

1.How does a printed circuit board assembly (PCB assembly) work?

![]()

The primary function of a PCB assembly is to integrate the electronic components of a device into a compact or defined space. Acting as the central hub of the electronic circuit of a device, the PCB provides insulation for all other electrical components, allowing them to be safely connected to a power source.

2. What information is required for a turnkey PCB assembly order?

For turnkey projects, we’ll need the following:

Gerber file

Bill of materials (BOM)

Component placement list (CPL)

All relevant CAD and .stp file

3. Are you UL / Underwriters Laboratory approved?

IBE pursues all applicable UL certifications for our products, and we offer several products certified with UL and CSA based on customer’s demand

Underwriters Laboratories (UL) grants multiple certifications, including:

IBE is certified for PCB by UL file E326838

4. Do you offer RoHS&REACH-compliant assemblies?

Yes, IBE does offer assemblies that comply with the European Union’s Restriction of Hazardous Substances (RoHS) Directive and REACH.