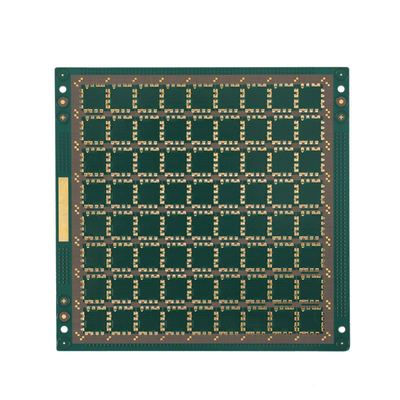

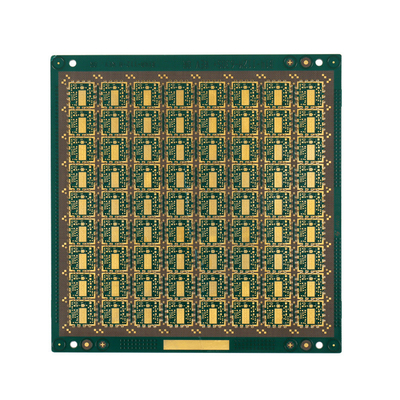

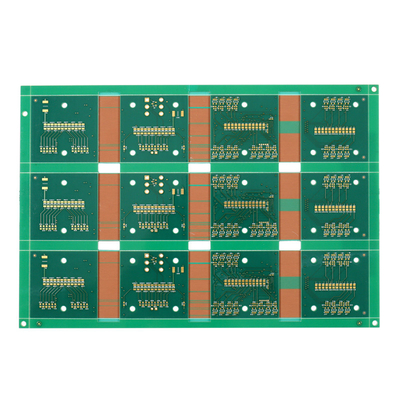

OEM High Tg HDI Multilayer PCBs Design HASL Immersion Gold

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Min. Line Width | 0.075mm/0.075mm(3mil/3mil) | Surface Finishing | ENIG |

|---|---|---|---|

| Copper Thickness | 1oz | Base Material | FR4 |

| Min. Line Spacing | 0.075mm | Board Thickness | 1.6mm |

| Min. Hole Size | 0.25mm | Soldermask Color | Green |

| Silkscreen Color | White | Layer | 1-32L |

| Highlight | High Tg HDI Multilayer PCBs,hdi pcb design HASL Immersion Gold,OEM High Tg hdi pcb design |

||

PCBA Capability

| PCB Manufacturing Capability | |

| PCB Layers: | 1Layers to 18 layer (Max) |

| Board thickness: | 0.13~6.0mm |

| Min line width/space: | 3mil |

| Min mechanical hole size: | 4mil |

| Copper thickness: | 9um~210um(0.25oz~6oz) |

| Max aspect ratio: | 1:10 |

| Max board size: | 400*700mm |

| Surface Finish: | HASL, immersion gold, immersion silver,immersion tin, flash gold, gold finger,peelable mask |

| Material: | FR4,High Tg, Rogers, CEM-1, CEM-3, Aluminum BT, PTFE. |

| PCB Assembly Capability | |

| Stencil size range: | 1560*450mm |

| Min SMT package: | 0402/1005(1.0x0.5mm) |

| Min IC pitch: | 0.3mm |

| Max PCB Size: | 1200*400mm |

| Min PCB thickness: | 0.35mm |

| Min Chip Size: | 01005 |

| Max BGA Size: | 74*74mm |

| BGA Ball Pitch: | 1.00~3.00mm |

| BGA Ball Diameter: | 0.4~1.0mm |

| QFP Lead Pitch: | 0.38~2.54mm |

| Testing : | ICT,AOI,X-RAY,Funtional test etc. |

|

Order Conditions

|

Standard Delivery Date

|

The fastest Delivery Date

|

|

Prototype ( <20pcs)

|

2days

|

8hours

|

|

Small Volume (20-100pcs)

|

6days

|

12hours

|

|

Medium Volume (100-1000)

|

3days

|

24hours

|

|

Mass Production (>1000)

|

Depends on BOM

|

Depends on BOM

|

FAQ:

1. What information is required for a turnkey PCB assembly order?

For turnkey projects, we’ll need the following:

Gerber file

Bill of materials (BOM)

Component placement list (CPL)

All relevant CAD and .stp file

2. Do you offer testing and inspection services?

Yes, IBE offers a comprehensive list of testing and inspection services for both SMT and through-hole assemblies.

Visual inspection/scanning microscopes

AOI inspection

In-circuit test

Functional testing include automated test equipment and system

Burn-in tests

Low/High Temp Chamber Testing

X-ray inspection and repair

Salt fog tester

Drop Test

packing vibration

Conformal coating and potting

3. What are your PCB assembly standards?

IBE has obtained the following IPC electronics industry standards for PCB assembly

IPC-A-600G for PCB production

IPC-620 for practices and requirements for cables, wire, and harness assembly manufacturing

IPC-A-610E PCBA Acceptability of Electronic Assemblies