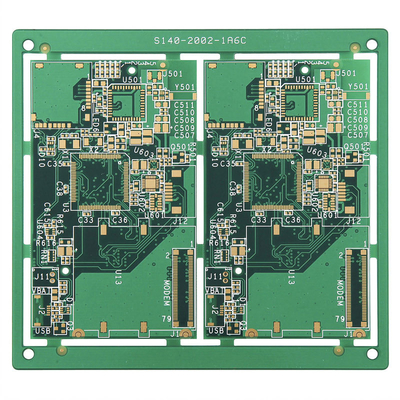

1oz Multilayer Pcb Fabrication 12 Layer Circuit Board ISO TS16949

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Min. Line Width | 0.075mm/0.075mm(3mil/3mil) | Surface Finishing | ENIG |

|---|---|---|---|

| Copper Thickness | 1oz | Base Material | FR4 |

| Min. Line Spacing | 0.075mm | Board Thickness | 1.6mm |

| Min. Hole Size | 0.25mm | Soldermask Color | Green |

| Silkscreen Color | White | Layer | 1-32L |

| Highlight | 1oz Multilayer Pcb Fabrication,12 Layer Circuit Board ISO TS16949,1oz 12 Layer Circuit Board |

||

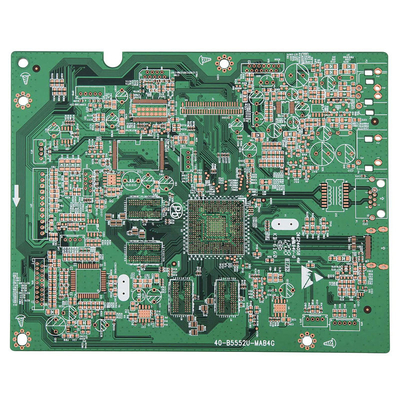

One-Stop fr4 high tg multilayer pcb fabrication 12layers pcb

![]()

| PCB Manufacturing Capability | |

| PCB Layers: | 1Layers to 18 layer (Max) |

| Board thickness: | 0.13~6.0mm |

| Min line width/space: | 3mil |

| Min mechanical hole size: | 4mil |

| Copper thickness: | 9um~210um(0.25oz~6oz) |

| Max aspect ratio: | 1:10 |

| Max board size: | 400*700mm |

| Surface Finish: | HASL, immersion gold, immersion silver,immersion tin, flash gold, gold finger,peelable mask |

| Material: | FR4,High Tg, Rogers, CEM-1, CEM-3, Aluminum BT, PTFE. |

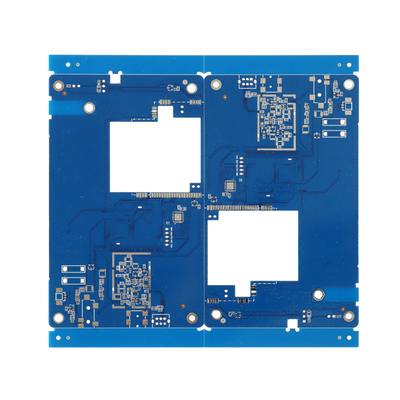

| PCB Assembly Capability | |

| Stencil size range: | 1560*450mm |

| Min SMT package: | 0402/1005(1.0x0.5mm) |

| Min IC pitch: | 0.3mm |

| Max PCB Size: | 1200*400mm |

| Min PCB thickness: | 0.35mm |

| Min Chip Size: | 01005 |

| Max BGA Size: | 74*74mm |

| BGA Ball Pitch: | 1.00~3.00mm |

| BGA Ball Diameter: | 0.4~1.0mm |

| QFP Lead Pitch: | 0.38~2.54mm |

| Testing : | ICT,AOI,X-RAY,Funtional test etc. |

|

Order Conditions

|

Standard Delivery Date

|

The fastest Delivery Date

|

|

Prototype ( <20pcs)

|

2days

|

8hours

|

|

Small Volume (20-100pcs)

|

6days

|

12hours

|

|

Medium Volume (100-1000)

|

3days

|

24hours

|

|

Mass Production (>1000)

|

Depends on BOM

|

Depends on BOM

|

FAQ:

1.How does a printed circuit board assembly (PCB assembly) work?

![]()

The primary function of a PCB assembly is to integrate the electronic components of a device into a compact or defined space. Acting as the central hub of the electronic circuit of a device, the PCB provides insulation for all other electrical components, allowing them to be safely connected to a power source.

2. What information is required for a turnkey PCB assembly order?

For turnkey projects, we’ll need the following:

Gerber file

Bill of materials (BOM)

Component placement list (CPL)

All relevant CAD and .stp file

3. Do you offer testing and inspection services?

Yes, IBE offers a comprehensive list of testing and inspection services for both SMT and through-hole assemblies.

Visual inspection/scanning microscopes

AOI inspection

In-circuit test

Functional testing include automated test equipment and system

Burn-in tests

Low/High Temp Chamber Testing

X-ray inspection and repair

Salt fog tester

Drop Test

packing vibration

Conformal coating and potting

4.Where do you manufacture your products?

We have production plant based in shenzhen,China; Fremont,US,Bac Ninh,Vietn